- Item Code: CI0017

- Pressure Rating: CL-125

- Testing Standard: Mfg. Standard

- Size Range: 25mm to 600mm

- Product Standard: DIN EN 12334

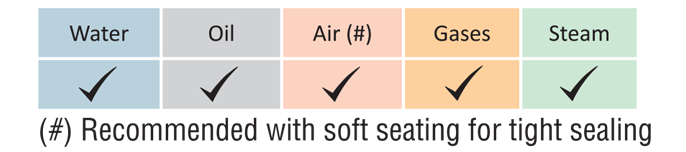

Suitable For

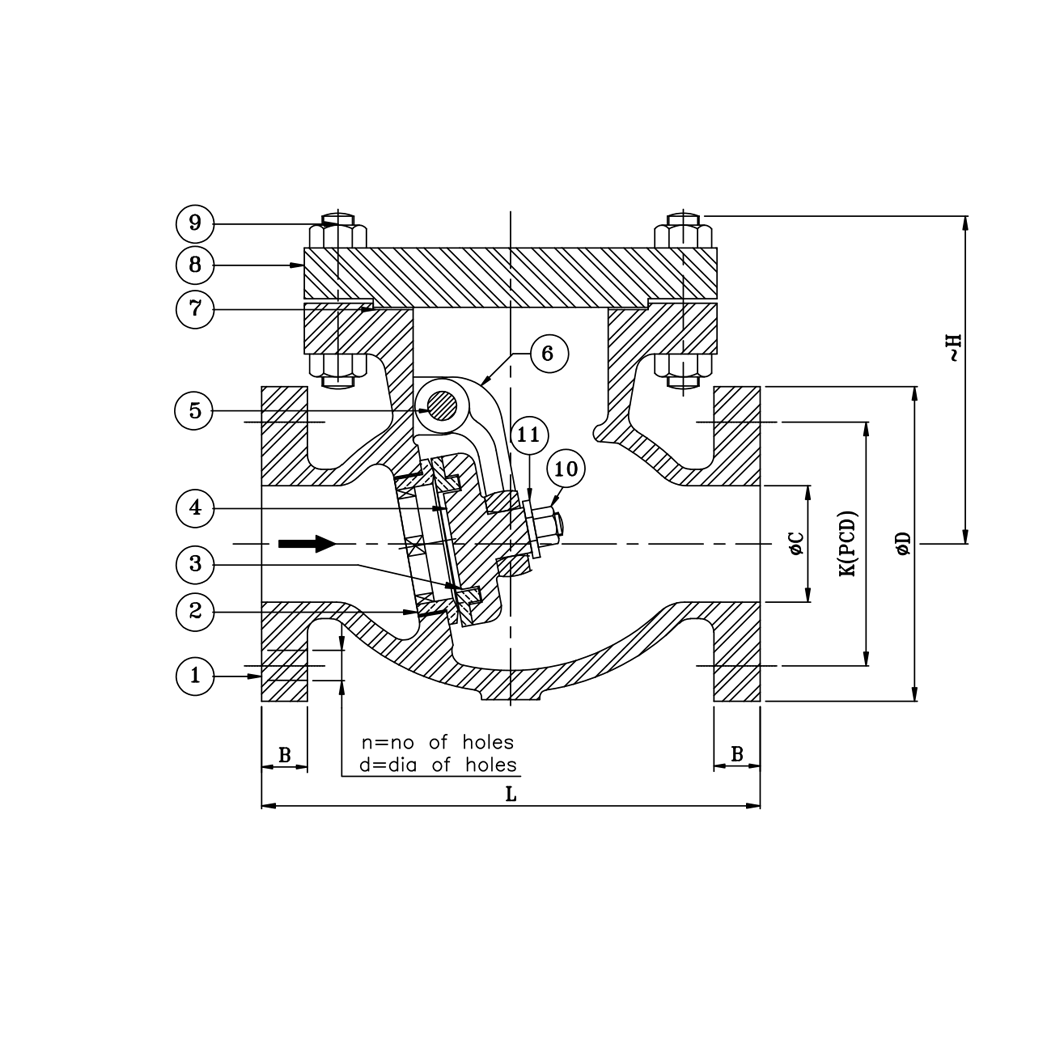

Material Specification

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | CAST IRON | IS 210 Gr. FG200 |

| 2 | BODY SEAT RING | G.M./S.S. | BSEN 1982 CC491K / 13% Cr. STEEL |

| 3 | DISC FACING RING | G.M./S.S. | BSEN 1982 CC491K / 13% Cr. STEEL |

| 4 | DISC | CAST IRON | IS 210 Gr. FG200 |

| 5 | HINGE | C.C.S./CAST IRON | ASTM A216 Gr. WCB/FG 200 |

| 6 | HINGE PIN | HT BRASS / S.S. | BSEN 1982 CC491K / 13% Cr. STEEL |

| 7 | GASKET | C.N.A.F. | BS 1832 |

| 8 | COVER | CAST IRON | IS 210 Gr. FG200 |

| 9 | STUDS & NUTS | CARBON STEEL | BS 916 |

| 10 | NUTS | HT BRASS | BS 2872 Gr. CZ114 |

| 11 | WASHER | BRASS / G.M. | IS 2062 Gr. A |

Dimensional Data

| SIZE (mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 152±1.6 | 180±1.6 | 165±1.6 | 203±1.6 | 216±1.6 | 241±1.6 | 292±1.6 | 330±1.6 | 356±1.6 | 495±1.6 | 622±1.6 | 698±3.2 | 787±3.2 | 914±3.2 | 965±3.2 | 1067±3.2 | 1295±3.2 |

| ~H | 95 | 112 | 110 | 115 | 135 | 135 | 190 | 192 | 200 | 265 | 335 | 365 | 415 | 470 | 495 | 600 | 680 |

| ∅C | 25.4 | 32 | 38 | 51 | 63.5 | 76 | 101.5 | 127 | 152 | 203 | 254 | 305 | 355.5 | 406.5 | 457 | 508 | 600 |

| ∅D | 110 | 115 | 127 | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 698.5 | 812.8 |

| B | 11.1 | 12.7 | 14.3 | 15.9 | 17.5 | 19 | 23.8 | 23.8 | 25.4 | 28.6 | 30.2 | 31.8 | 34.9 | 36.5 | 39.7 | 43 | 47.8 |

| K | 79 | 88.9 | 98 | 121 | 140 | 152 | 191 | 216 | 241 | 299 | 362 | 432 | 476 | 540 | 578 | 635 | 749.3 |

| n | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 |

| d | 15.9 | 15.9 | 15.9 | 19 | 19 | 19 | 19 | 22.2 | 22.2 | 22.2 | 25.4 | 25.4 | 28.6 | 28.6 | 31.8 | 31.8 | 35 |

Principle Features

INTRODUCTION

Leader Swing Check Valves are designed with high sensitivity to pressure so that the valve closes immediately before significant fluid starts flowing backward. Fluid reversing backward causes damage to equipment like boilers or pumps. The valve is activated by the flowing material in the pipeline. The pressure of the fluid passing through the system opens the valve, while any reversal of flow will close the valve. Closure is accomplished by the weight of the check mechanism, by back pressure. Entirely automatic in action, depending upon differential pressure and velocity of flow within the line to perform their functions of opening and closing.

- Design Std.: DIN EN 12334.

- Bolted Cover, Swing Disc design.

- Metal to Metal seating.

- Gun Metal Body & Disc rings.

- Design Prohibits Galling or Scoring of Seating Surfaces.

- One-Piece Disc Construction Designed to Withstand Severe Service Conditions.

- Large Bolted-On Cover Provides Easy Access to Interior for Routine Maintenance.

- Rigid & Sturdy design.

- Long service life as wear is minimal which makes it highly reliable.

- Valve is mechanically automatic and thus it does not need an actuator or valve operator.

- A horizontal or vertical duct can be used, easy to install.

- The valve must be installed in the direction of the flow arrow.

- Flanged ends as per ASME B16.1 CL-125 (FF).

- Valves are available with IBR Certification up to size 200mm.

- Widely applied for low-pressure and ambient-temperature utility services such as water supply, power plants, gas supply, district heating piping, irrigation projects, air conditioning systems, as well as food processing industry, chemical and petrochemical industry, Boiler industry, pharmaceutical, and powder industry to prevent the backflow.

END CONNECTION

- Flanged ends as per ASME B16.1 CL-125 FF.

- Flange drilling as per other standards also available upon request.

UTILISATION & SERVICE

- Best suited for potable water, treated fresh water, neutral liquids Steam & some gases.

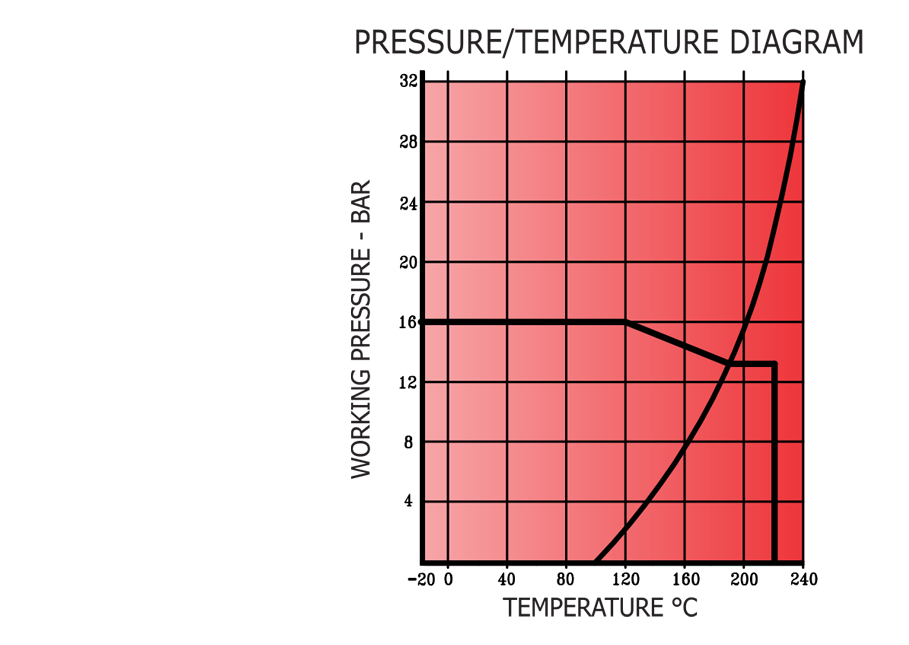

WORKING PRESSURE

- Maximum Working Pressure: 12.54 Bar.

- See Pressure / Temperature Diagram.

TEMPERATURE LIMITS

- Maximum Working Temperature: 220°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | CL-125 |

|---|---|

| Body (Hyd.) | 24.1 Bar |

| Seat (Hyd.) | 13.8 Bar |