- Item Code: FCS001

- Pressure Rating: CL-600

- Testing Standard: API-598, BSEN 12266 Part-1

- Size Range: 15mm to 50mm

- Product Standard: ASME B16.34

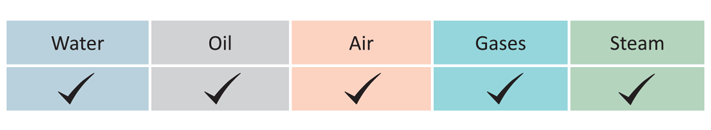

Suitable For

Material Specification

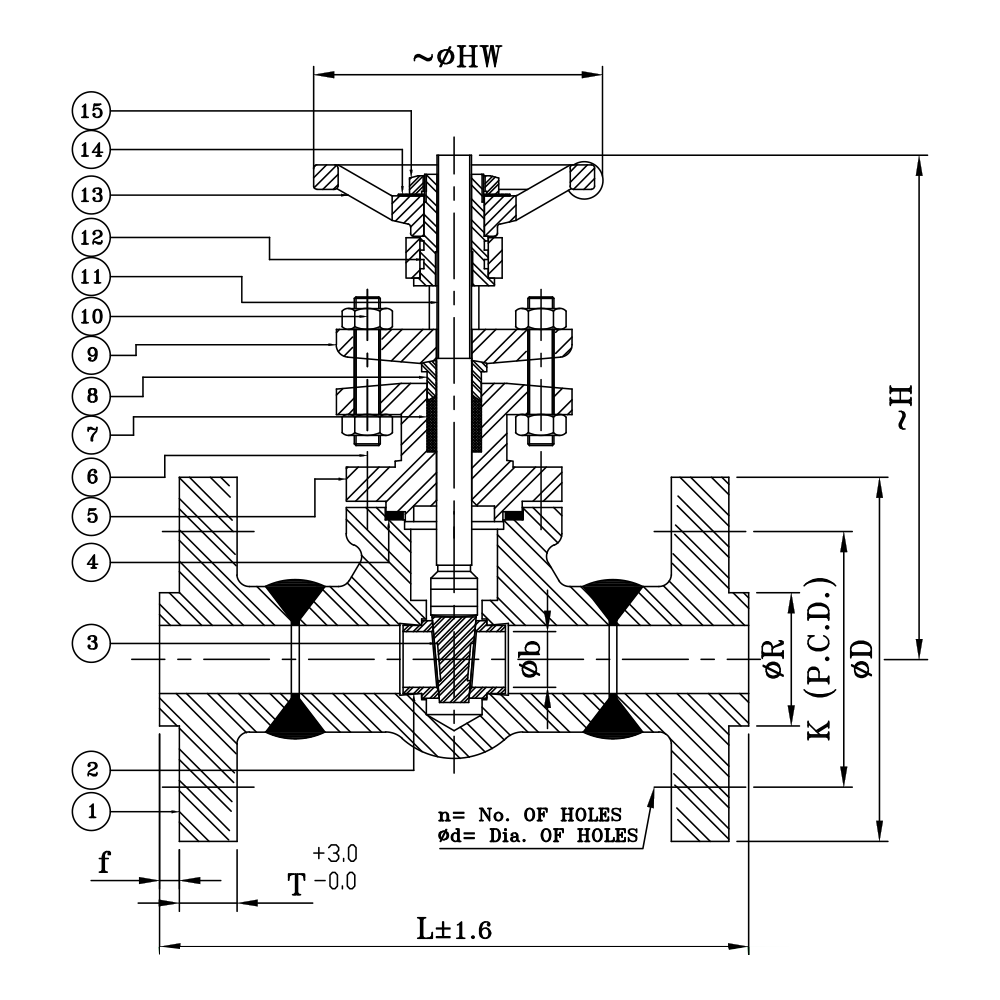

| P. No. | NAME OF PART | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | BODY | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 2 | SEAT RING | ASTM A276 TYPE 410 | SS 304 | SS 410 | SS 410 | SS 410 | SS 410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 3 | WEDGE | ASTM A217 Gr. CA15/ ASTIM 276 TYPE 410 |

SS 304 | CA15/ SS410 |

CA15/ SS410 |

CA15/ SS410 |

CA15/ SS410 |

SS 304 | SS 316 | SS 304L | SS 316L |

| 4 | GASKET | SPIRAL WOUND STAINLESS STEEL GRAPHOIL FILLER | |||||||||

| 5 | BONNET | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 6 | STUDS | A193 B7 | A320 L7 | A193 B7 | A193 B7 | A193 B16 | A193 B16 | A193 B8 | A193 B8 | A193 B8 | A193 B8 |

| 7 | PACKING | FLEXIBLE GRAPHITE | |||||||||

| 8 | GLAND | A182 F6a | SS 304 | A182 F6a | A182 F6a | A182 F6a | A182 F6a | SS 304 | SS 316 | SS 304L | SS 316L |

| 9 | GLAND FLANGE | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 10 | NUTS | A194 2H | A194 Gr.4 | A194 2H | A194 Gr.4 | A194 Gr.4 | A194 Gr.4 | A194 Gr.8 | A194 Gr.8 | A194 Gr.8 | A194 Gr.8 |

| 11 | STEM | ASTM A276 TYPE 410 | SS 304 | SS 410 | SS 410 | SS 410 | SS 410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 12 | YOKE SLEEVE | ASTM A582 TYPE 416 | |||||||||

| 13 | HAND WHEEL | DI.A536 Gr. 80-55-06 | |||||||||

| 14 | NAME PLATE | ALUMINIUM / STEEL | |||||||||

| 15 | HAND WHEEL RETAINING NUT | STEEL | |||||||||

Dimensional Data

| SIZE (mm) | 15 | 20 | 25 | 32 | 40 | 50 |

|---|---|---|---|---|---|---|

| L | 165 | 190 | 216 | 229 | 241 | 292 |

| ~H | 145 | 170 | 192 | 220 | 220 | 252 |

| ∅b | 12.5 | 18 | 24 | 31 | 33 | 35 |

| ~∅HW | 90 | 95 | 108 | 125 | 125 | 125 |

| ∅D | 95 | 117 | 124 | 133 | 155 | 165 |

| T | 14.2 | 15.7 | 17.5 | 20.6 | 22.4 | 25.4 |

| ∅R | 35.1 | 42.9 | 50.8 | 63.5 | 73 | 91.9 |

| f | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 |

| K | 66.5 | 82.6 | 88.9 | 98.6 | 114.3 | 127 |

| n | 4 | 4 | 4 | 4 | 4 | 8 |

| ∅d | 15.7 | 19.1 | 19.1 | 19.1 | 22.3 | 19.1 |

Principle Features

INTRODUCTION

Leader forged steel gate valves adopt solids gate, renewable seat, rising stem, and non-ring hand wheel. It plays the role of pipe opening and closing ultimately through the rotation of the hand wheel to drive the lifting of the gate.

- Design Std API 602. BSEN ISO 15761, ASME B16.34.

- Pressure Temperature Rating as per ASME B16.34, API 602.

- Sturdy design for high-pressure & temperature service.

- Bolted body-bonnet O&S Yoke type rising stem design, Valves with welded bonnet also available on request.

- Bolted body-bonnet joints provided with spiral-wound stainless steel gasket and graphite filler for protection against leaks.

- Die-formed graphite inner packing rings and braided graphite and rings with Inconel wire reinforcement and corrosion inhibitor.

- T-head stem-disc connection of gate valve fully meets strength requirements of API 602 and API 598.

- Tapered shoulder on the stem for back seating.

- The gland, gland flange assembly utilizes a separate, two-piece design. This self-aligning design allows the flange to be unevenly tightened while the gland maintains its parallel alignment with the stem and stuffing box.

- The yoke sleeve is of forged stainless steel material having a high melting point and is resistant to wear and corrosion.

- Flanged ends as per ASME B16.5 Raised Face.

- Robust construction of hand wheel in open spoke design.

- Valves can be offered with electrical actuators on request.

- Low-Temperature Carbon Steel & Austenitic SS forging for body and bonnet with extended bonnet design qualified as per BS 6364 for Cryogenic service available on request.

- Valves can be offered to NACE MR-0175 and other special NACE requirements.

- Valves are available with IBR certification.

- Low Emission, FET qualified valves as per API 624/150 15848-1 can be offered with API 622 (FET), API 607 (Fire Safe) qualified gland packing.

TEST PRESSURE(Hydrostatic)

| Rating | CL-600 |

|---|---|

| Body (Hyd.) | 154 Bar |

| Seat (Hyd.) | 113 Bar |

| Seat (Air) | 6.9 Bar |

END CONNECTION

- Welded on flanges as per ASME B16.5 Raced Face.

WORKING PRESSURE

- Maximum working pressure 103 Bar (CL-600).

TEMPERATURE LIMITS

- Maximum working temperature 425°C.

TRIM MATERIAL COMBINATION (ON REQUEST)

| Trim No. | Seat Ring Face | Wedge Seat Face | Stem | Backseat Bush | Lantern Ring |

|---|---|---|---|---|---|

| 2 | F304 | F304 | F304/AISI304 | F304/AISI304 | F304/AISI304 |

| 5 | STELLITE(#6) | STELLITE(#6) | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 8 | STELLITE(#6) | F6a/13%Cr. | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 9 | MONEL | MONEL | MONEL | MONEL | MONEL |

| 10 | F316 | F316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 12 | 316+Stellite(#6) | 316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 13 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 |