- Item Code: CI0036

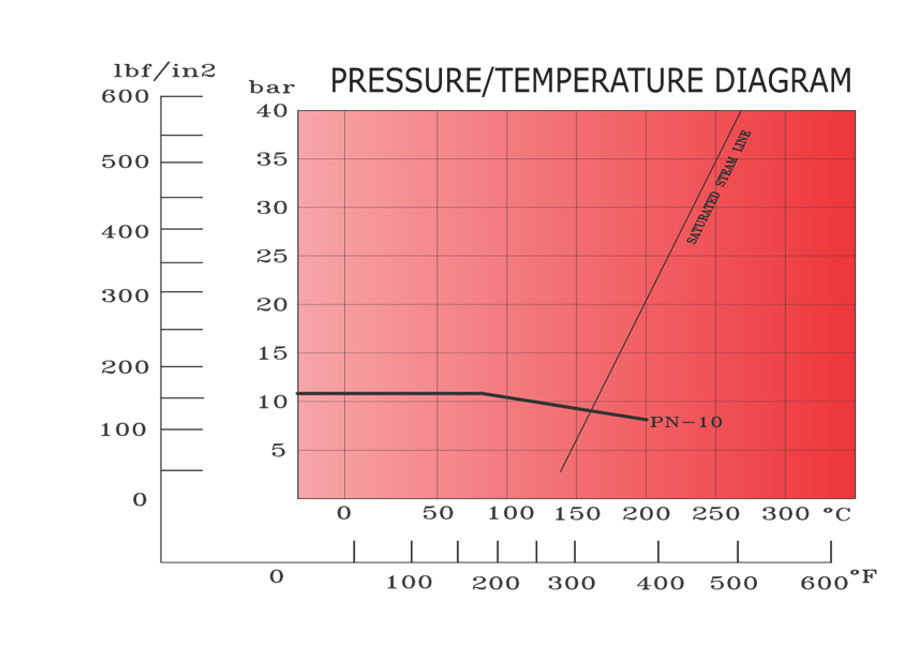

- Pressure Rating: PN-10

- Testing Standard: Mfg. Standard

- Size Range: 25mm to 100mm

- Product Standard: Mfg. Standard

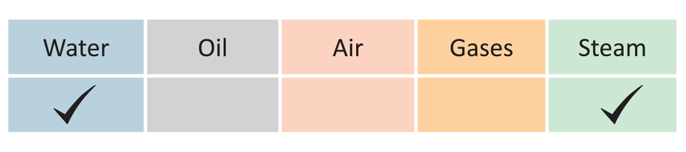

Suitable For

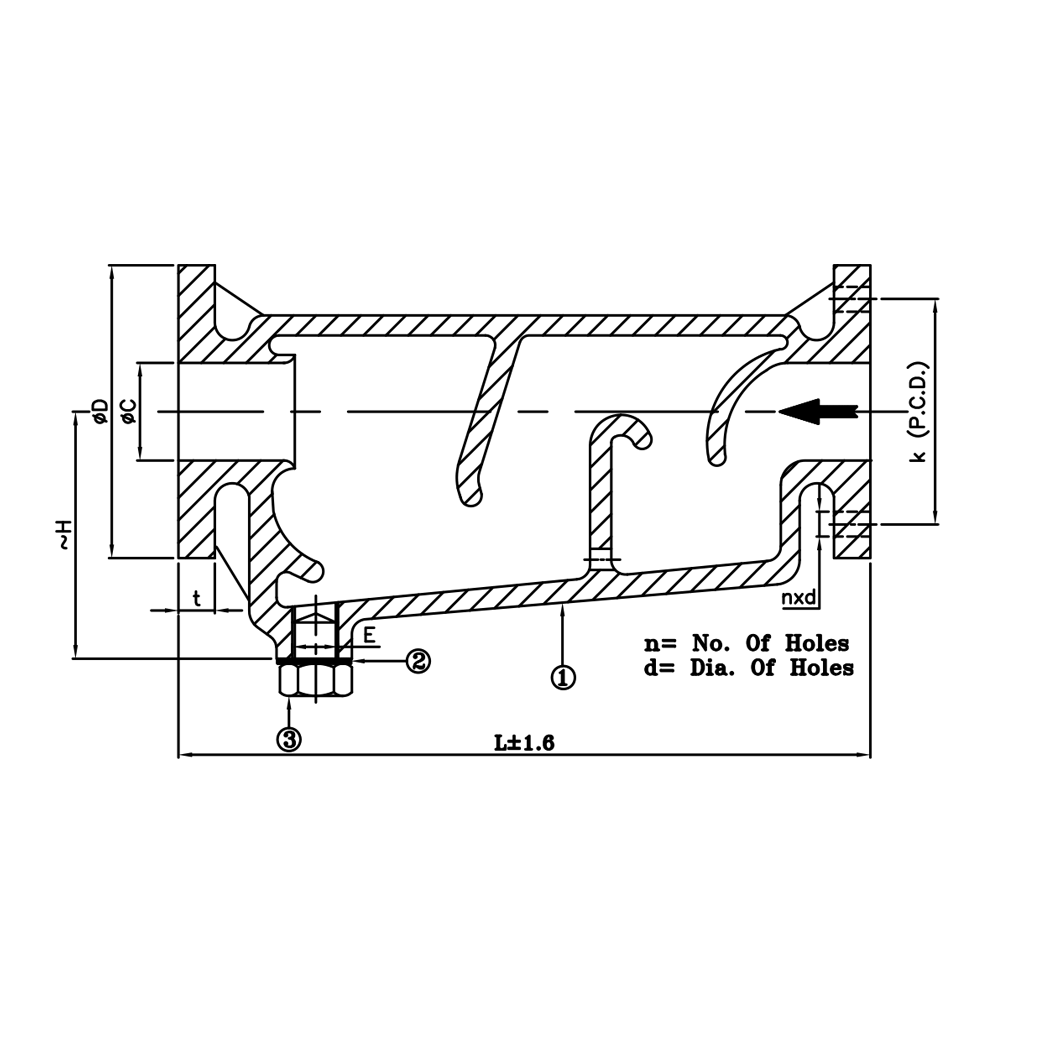

Material Specification

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | CAST IRON | IS 210 Gr. FG260 |

| 2 | GASKET | C.N.A.F. | BS 1832 |

| 3 | PLUG | GUN METAL | BSEN 1982 Gr. CC260491K |

Dimensional Data

| SIZE (mm) | 25 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|

| L±1.6 | 275 | 370 | 466 | 485 | 485 | 692 |

| ~H | 78 | 113 | 146 | 172 | 175 | 238 |

| ∅C | 25 | 38 | 50 | 65 | 76 | 100 |

| E | 1/2" B.S.P. | 1/2" B.S.P. | 1/2" B.S.P. | 1/2" B.S.P. | 1" B.S.P. | 1" B.S.P. |

| ∅D | 115 | 150 | 165 | 185 | 200 | 220 |

| t | 16 | 18 | 20 | 20 | 22 | 24 |

| k | 85 | 110 | 125 | 145 | 160 | 180 |

| n | 4 | 4 | 4 | 4 | 8 | 8 |

| d | 14 | 19 | 19 | 19 | 19 | 19 |

Principle Features

INTRODUCTION

Leader Steam Moisture Separators are used for the removal of entrained liquid or solids from steam. When a vapor entrained with moisture enters the steam separator, a series of baffles change its flow direction several times. During the process, the baffles in the housing collect impinged water droplets that are carried in the vapor. Gravity causes the accumulated water droplets and other foreign particles to fall into the drain and exit through an external trap. This allows clean, dry vapor to exit at the outlet of the separator.

- Design Standard: Mfg. Standard.

- Baffle type design.

- Horizontal Installation.

- Removes 99% of all particles > 10 microns in size.

- Optimal gravity discharge.

- Long-lasting cast iron construction.

- Available with IBR III-C certificate.

- Flanges as per BS:4504 PN-10 (FF) Drilled.

END CONNECTION

- Flanges as per BS:4504 PN-10 (FF) Drilled.

UTILISATION & SERVICE

- “LEADER” Cast Iron Moisture separators are suitable for above-ground installations.

- Best suited for potable water, treated fresh water, neutral liquids & some gases.

WORKING PRESSURE

- Maximum Working Pressure: 10 Bar.

- See Pressure / Temperature Diagram.

TEMPERATURE LIMITS

- Maximum Working Temperature: 220°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | PN-10 |

|---|---|

| Body (Hyd.) | 22 Bar |